In preparation for the final deliverables, which are due by the end of December for LabLand, the group of 25 students was divided into smaller teams.

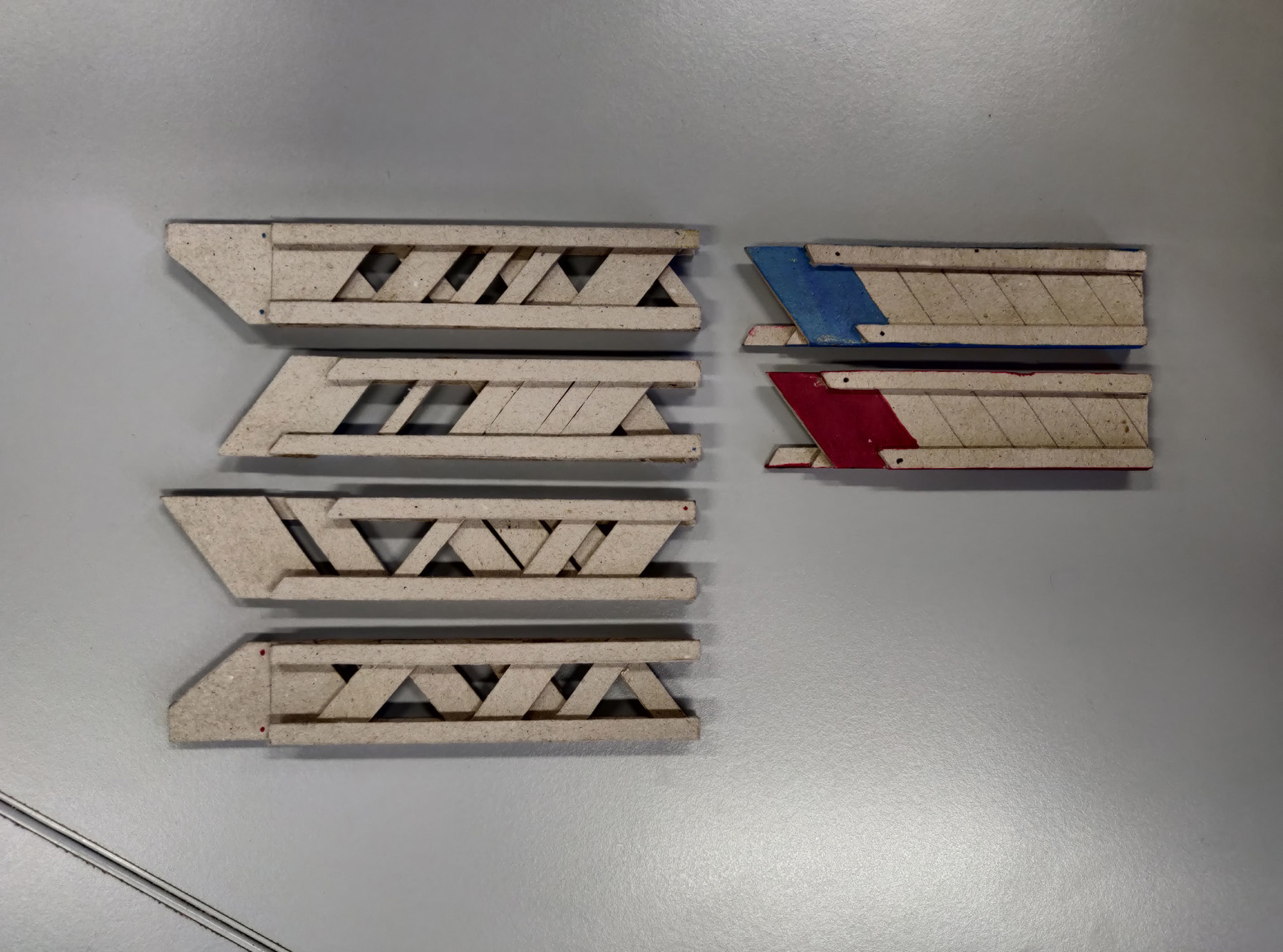

Three groups were tasked with fine-tuning and producing their individual concepts. Which included designing a chair, a cabinet, and facade shingles. The remaining 20 students were split into subgroups responsible for the preparation of the structural columns production.

The next step involved the design team, which worked on refining their respective concepts. This group collaborated closely with the team responsible for strength testing and the team working on creating the jigs for production. Additionally, there were groups dedicated to sourcing the wood and managing the inventory. Those students were responsible for maintaining the stock of reused wood.

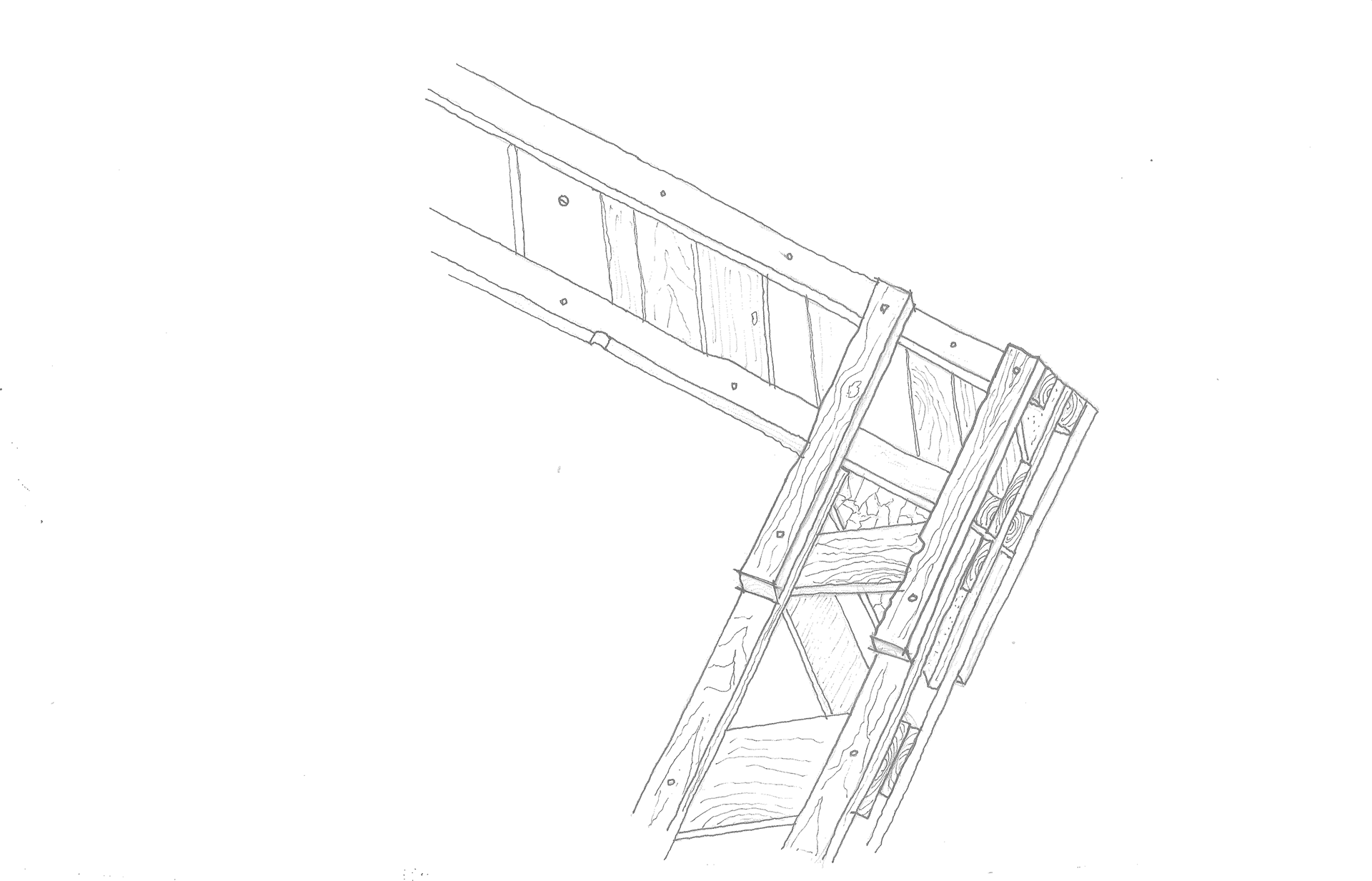

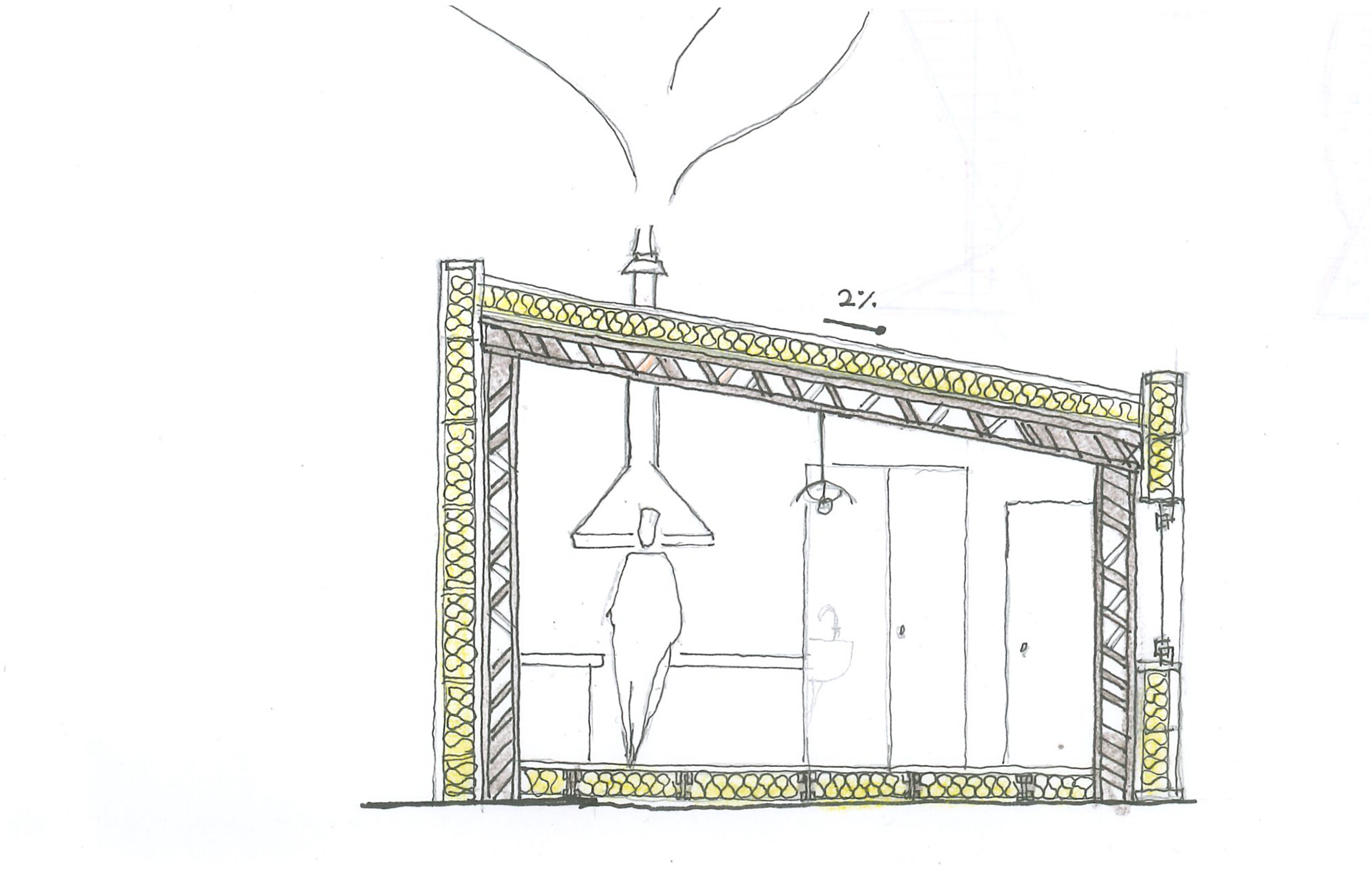

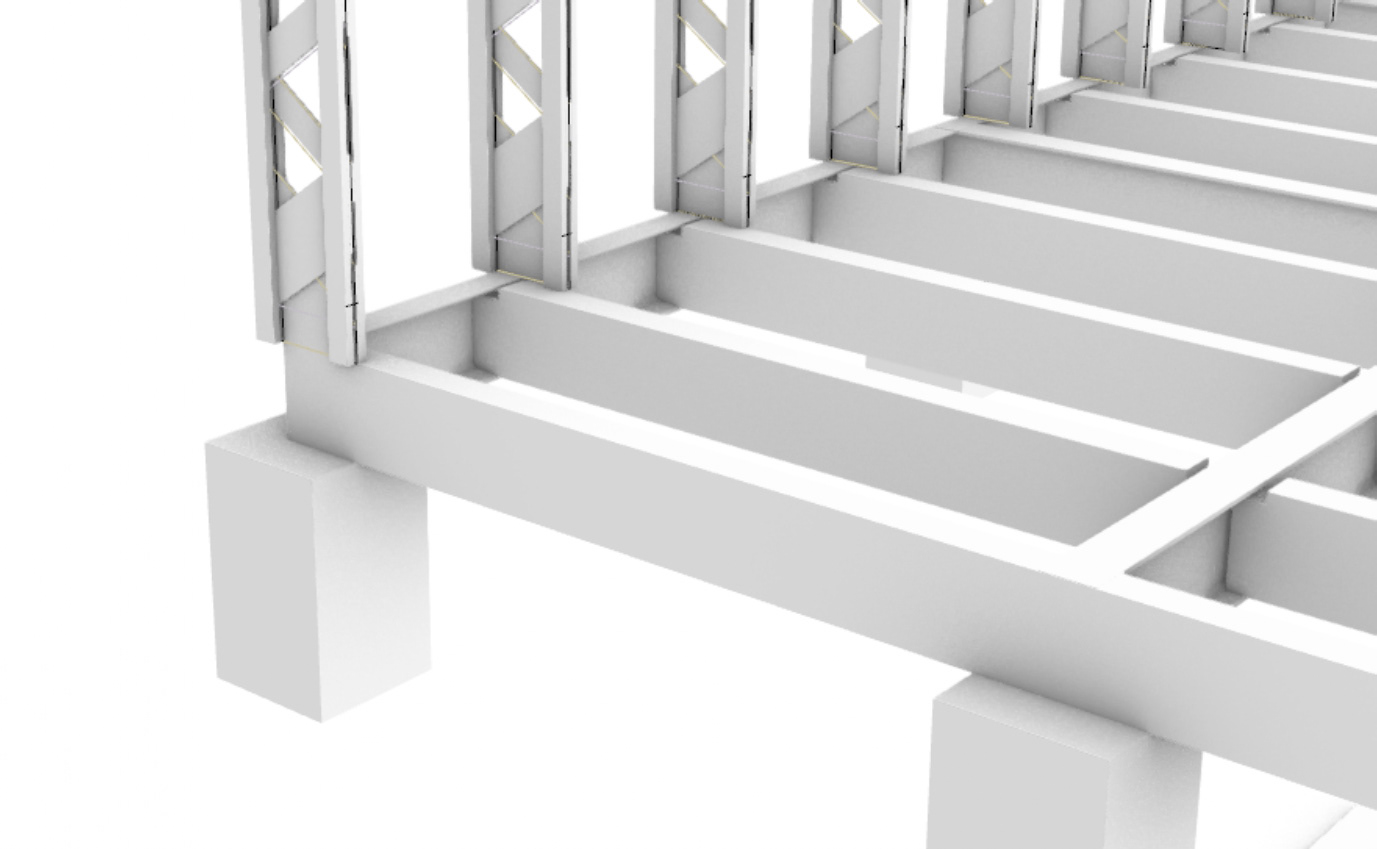

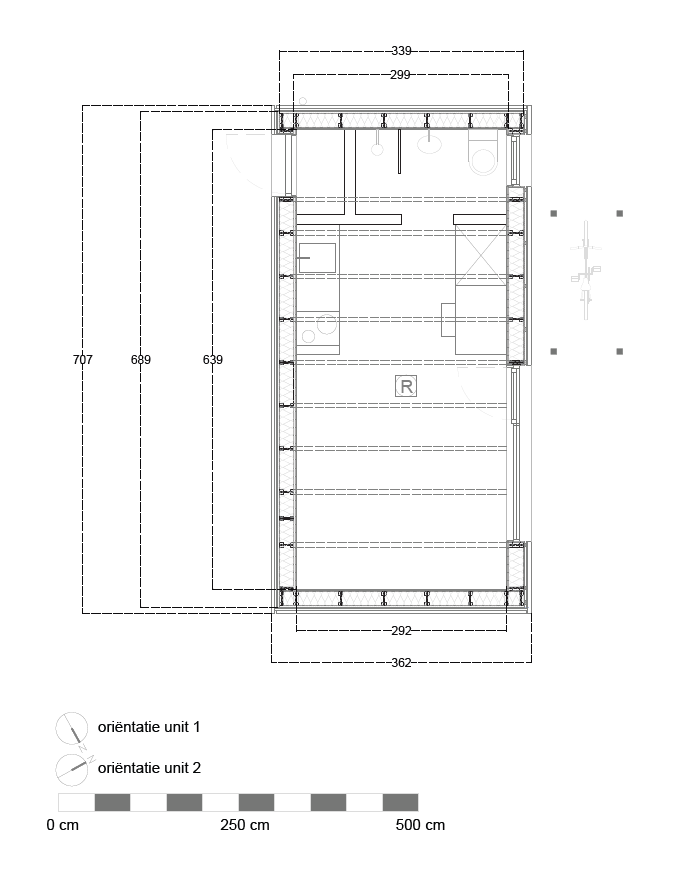

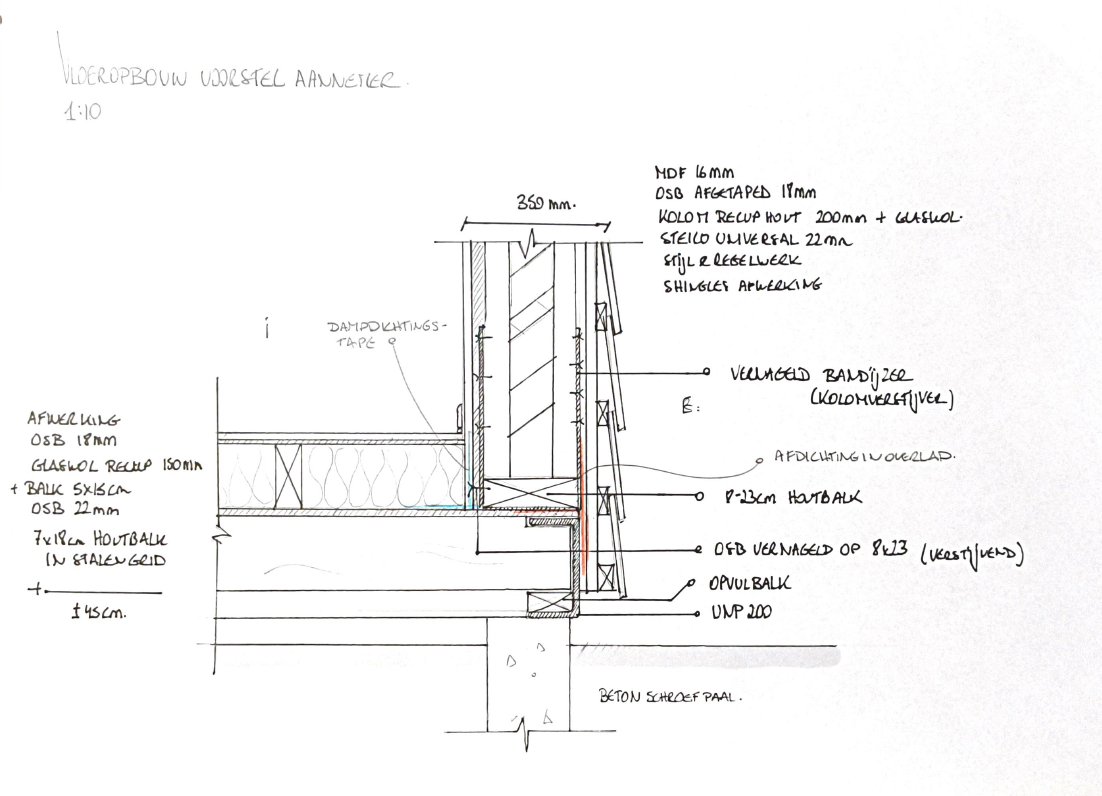

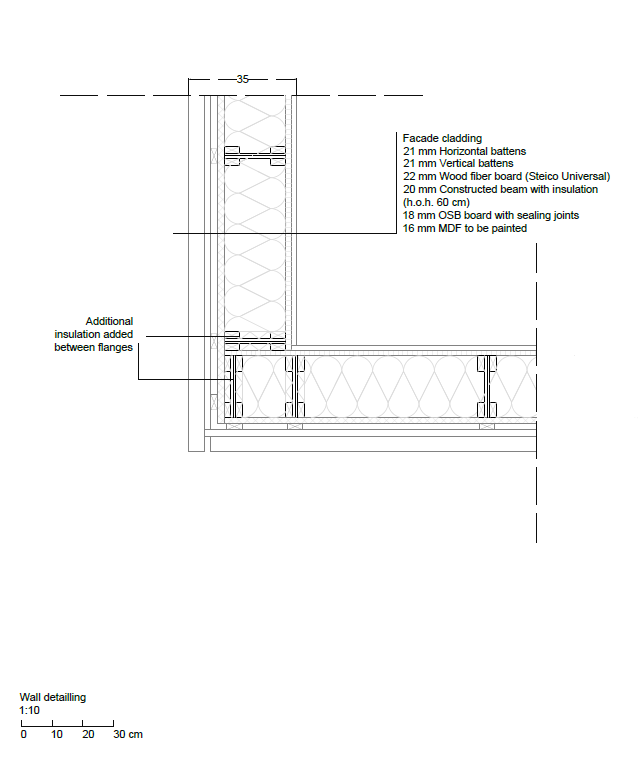

Final model

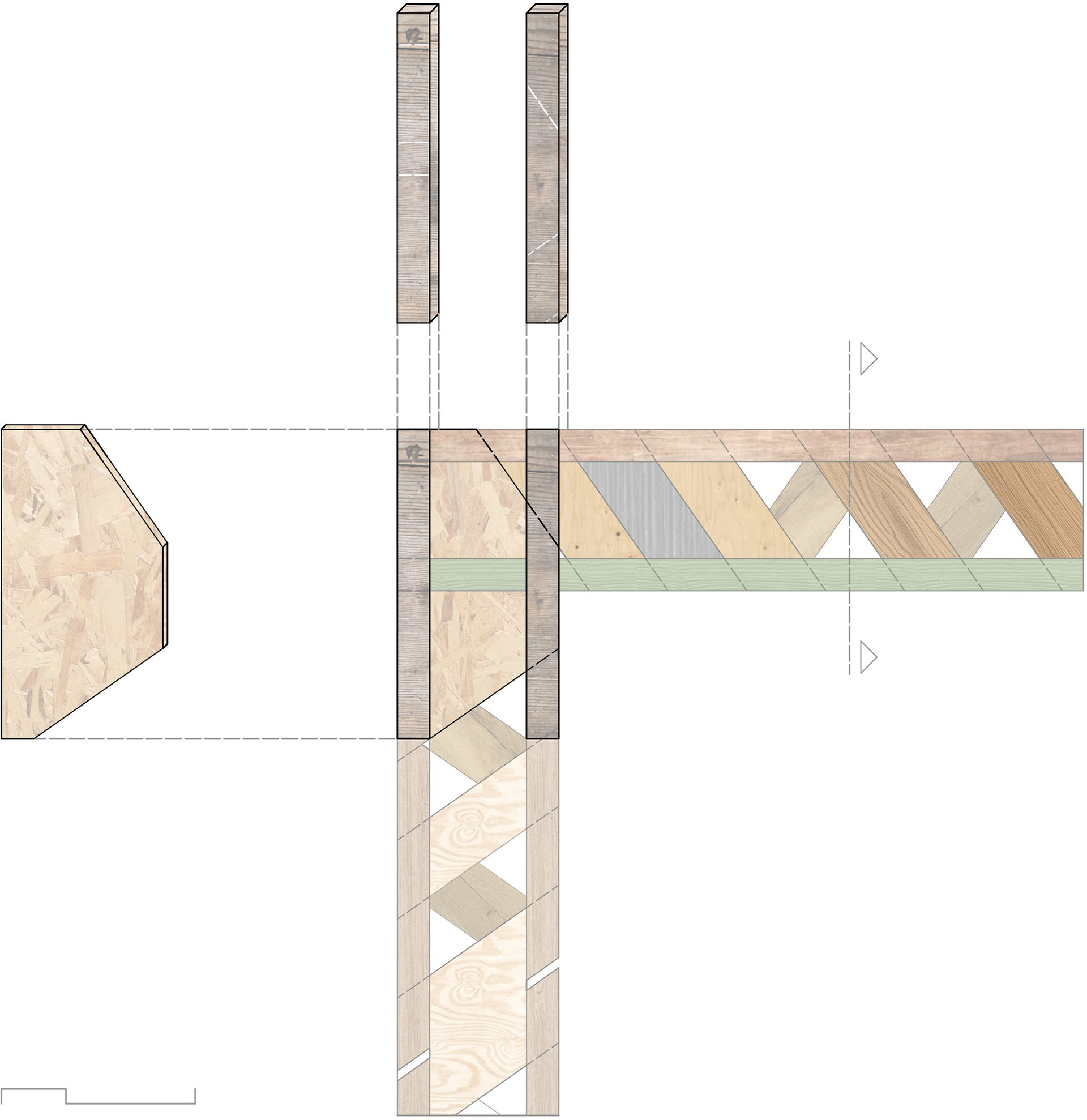

3D model

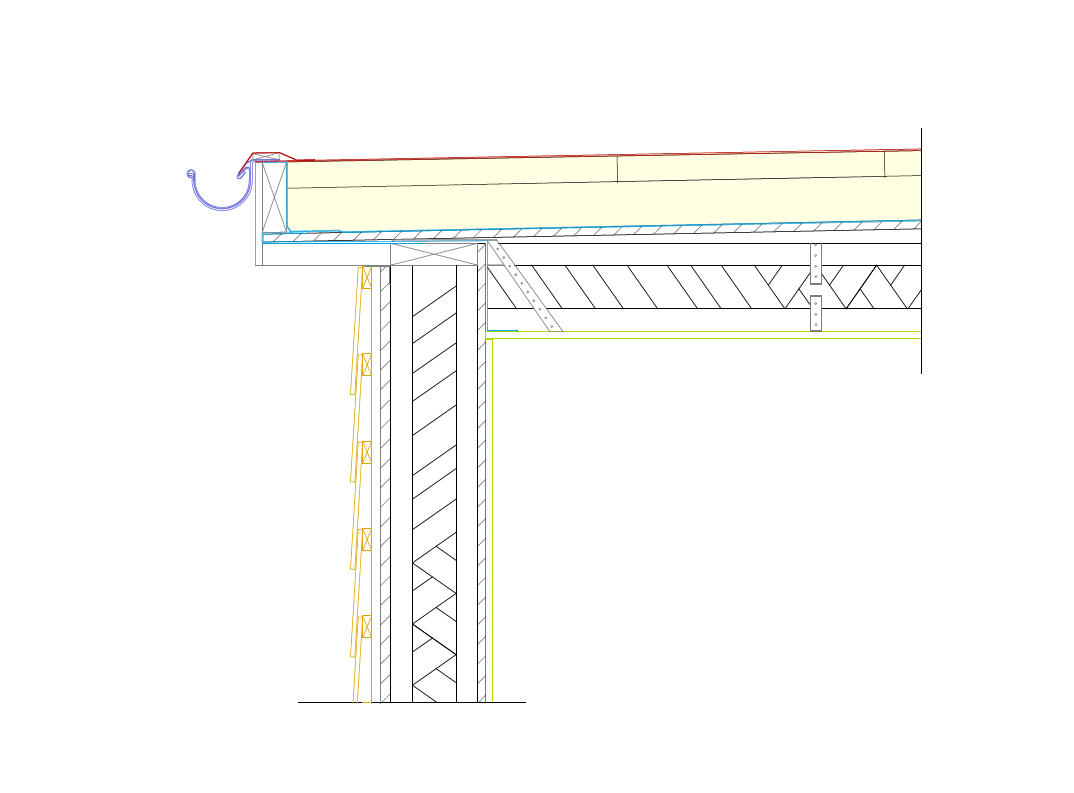

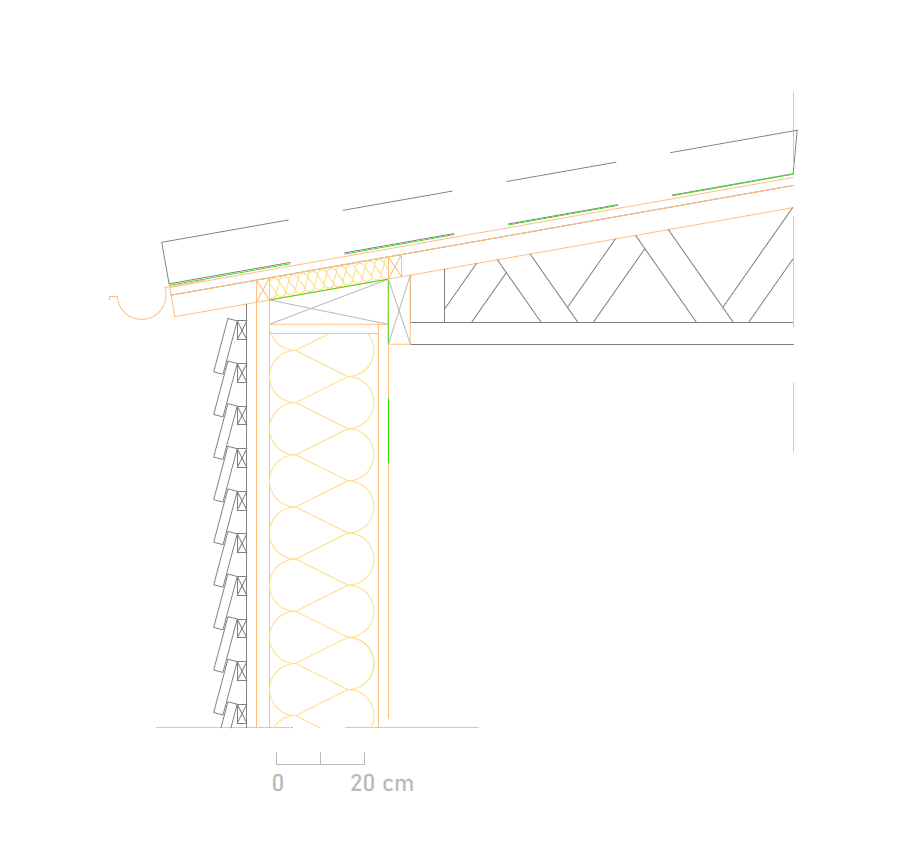

Details

The construction manual of the column

Strength test

The wood

Inventory

Progress of the model

Progress of the idea